Introduction 3D printing is a rapidly growing technology that has the potential to revolutionize various industries, including healthcare, construction, manufacturing, art, and fashion. In this comprehensive guide, we will explore the various aspects of 3D printing, including its definition, history, and types of technologies used, as well as its various applications and benefits. Additionally, we will discuss the challenges and limitations of this innovative technology, as well as its future potential and ethical considerations.

A Brief History of 3D Printing

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by depositing layers of material. The technology was first developed in the 1980s, but it wasn’t until the 21st century that it began to gain widespread attention and recognition. Today, 3D printing is used in a wide range of industries, from healthcare and construction to fashion and art.

Types of 3D Printing Technologies and Materials Used

There are several different types of 3D printing technologies, including Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Directed Energy Deposition (DED). The materials used in 3D printing vary depending on the technology and application, but common materials include plastics, metals, ceramics, and even food.

Types of 3D Printing Technologies

- Fused Deposition Modeling (FDM) - It is the most commonly used 3D printing technology that works by heating and extruding plastic filament.

- Stereolithography (SLA) - It uses a laser to cure resin into a solid form, layer by layer.

- Selective Laser Sintering (SLS) - It uses a laser to sinter powdered materials into a solid form, layer by layer.

- Direct Energy Deposition (DED) - It uses a laser or electrode to melt metal or plastic material, layer by layer.

- PolyJet Printing - It uses a jetting process to layer liquid photopolymer resin into a solid form.

Materials Used in 3D Printing

- Plastics - Polylactic acid (PLA), Acrylonitrile butadiene styrene (ABS), Nylon, Polycarbonate (PC)

- Metals - Steel, Titanium, Aluminum, Copper, Gold, and Silver

- Ceramics - Porcelain, Alumina, Zirconia, and Silica

- Composites - Carbon fiber, Glass fiber, and Wood fiber

- Resins - Photopolymer resins, Silicone, and Epoxy resins.

It is important to choose the right material and technology for a specific application to ensure the desired result. For example, a high-temperature-resistant material may be required for a functional prototype in the automotive industry, while a biocompatible material may be necessary for a medical implant.

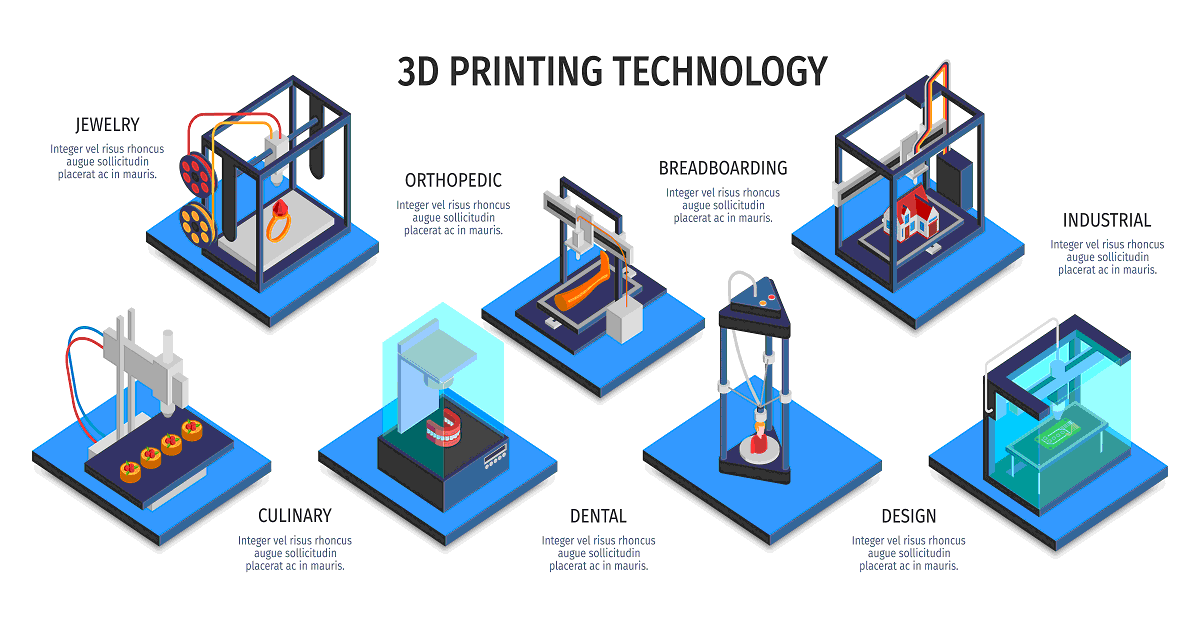

Applications of 3D Printing in Different Industries

3D printing has the potential to revolutionize a wide range of industries, including healthcare, construction, manufacturing, art, and fashion.

In the healthcare industry, 3D printing is used to create customized prosthetics, implants, and surgical tools, as well as to produce models for surgical planning. A case study of Oxford Performance Materials, a company that uses 3D printing technology to produce spinal implants, has shown a significant reduction in surgery time and improved patient outcomes.

In the construction industry, 3D printing is used to create building prototypes, as well as to produce molds and forms for concrete structures. This technology has the potential to reduce waste, lower costs, and speed up the building process.

In manufacturing, 3D printing is used to produce prototypes, molds, and parts for a wide range of products, from aerospace components to automotive parts. This technology offers significant cost savings, as well as the ability to produce complex and intricate designs.

In the art and fashion industries, 3D printing is used to create intricate and personalized designs that were previously difficult or impossible to achieve through traditional methods. For example, London-based design studio Nervous System has utilized 3D printing to create intricate, nature-inspired jewelry.

Benefits of 3D Printing

3D printing offers several key benefits, including customization, reduced waste, and cost savings. This technology enables the creation of highly customized products, as well as the ability to produce small quantities of specialized parts. Additionally, 3D printing reduces waste by enabling the production of only what is needed, and it reduces costs by eliminating the need for tooling and other manufacturing processes.

The benefits of 3D printing are numerous and wide-ranging, making it a valuable technology that has the potential to transform the world we live in. Whether it's improving healthcare, creating more sustainable products, or providing new and innovative design solutions, the possibilities of 3D printing are truly boundless.

Some of the key benefits include:

- Customization: 3D printing enables the creation of unique, customized products that are tailored to meet specific needs or preferences. This level of customization is not possible with traditional manufacturing methods, which often rely on mass production techniques.

- Reduced Waste: 3D printing is an additive manufacturing process, which means that it only uses the materials necessary to produce a product. This reduces waste and results in more efficient use of resources.

- Cost Savings: 3D printing can reduce the cost of production by eliminating the need for tooling and other manufacturing processes. This can result in significant cost savings, especially for low-volume production runs.

- Improved Speed: 3D printing can reduce the time it takes to produce a product, from design to delivery. This improved speed can help companies get products to market faster, giving them a competitive advantage.

- Enhanced Design Capabilities: 3D printing enables the creation of complex, intricate designs that would be difficult or impossible to achieve with traditional manufacturing methods. This opens up new possibilities for product design and innovation.

- Sustainable: 3D printing technology reduces waste by using only the materials required to produce a product. Additionally, the technology allows for on-demand production, reducing the need for large quantities of products to be manufactured and transported. This results in a more sustainable, environmentally friendly production process.

- Improving Healthcare: 3D printing has the potential to revolutionize the healthcare industry by enabling the production of customized medical devices and implants. For example, a case study of Oxford Performance Materials, a company that uses 3D printing to produce spinal implants, has shown a significant reduction in surgery time and improved patient outcomes.

Advancements and Future Potential of 3D Printing Technology

As technology continues to evolve and improve, the future potential of 3D printing is vast and limitless. With advancements in materials science, software, and hardware, 3D printing is becoming increasingly accessible and affordable for businesses and consumers alike.

One of the most exciting areas of growth for 3D printing is in the field of bioprinting, where scientists and researchers are using 3D printing technology to produce biological tissues and organs. This has the potential to revolutionize the healthcare industry and save countless lives by providing new and innovative solutions for patients in need of organ transplantations.

Another area of growth for 3D printing is in the production of customized and personal products. With 3D printing, it is now possible to create customized products on demand, such as personalized prosthetics and orthotics, as well as jewelry and other consumer goods. This offers a new level of personalization and customization, enabling consumers to create products that are tailored to their specific needs and preferences.

Challenges and Limitations of 3D Printing

Despite its many benefits and exciting potential, 3D printing technology still faces a number of challenges and limitations. One of the main challenges is the availability of materials, which can be expensive and limited in availability, especially for specialized applications.

Another challenge is intellectual property issues, as 3D printing technology makes it easier for individuals to produce and reproduce patented or trademarked products without authorization. This presents a significant challenge for businesses and industries that rely on the protection of their intellectual property.

Ethical Considerations and Potential Impacts on Society

As with any new and rapidly advancing technology, 3D printing raises a number of ethical considerations and potential impacts on society. For example, the ease and affordability of 3D printing technology may lead to the mass production of counterfeit and potentially dangerous products, posing a threat to consumer safety and the stability of industries that rely on the protection of their intellectual property.

Furthermore, the increasing accessibility and affordability of 3D printing technology has the potential to greatly impact the traditional manufacturing and retail industries, leading to job losses and economic disruption.

Case Studies and Examples of Successful 3D Printing Applications

There are countless examples of successful and innovative applications of 3D printing technology across a range of industries, including healthcare, construction, manufacturing, art, and fashion.

In the healthcare industry, 3D printing has been used to produce customized prosthetics, spinal implants, and other medical devices, leading to improved patient outcomes and reduced surgery time. A case study of Oxford Performance Materials, a company that uses 3D printing technology to produce spinal implants, has shown a significant reduction in surgery time and improved patient outcomes.

In the fashion industry, 3D printing has been used to create intricate and personalized designs that were previously difficult or impossible to achieve through traditional methods. For example, London-based design studio Nervous System has utilized 3D printing to create intricate, nature-inspired jewelry.

In the construction industry, 3D printing technology has been used to produce prototypes, models, and even entire building structures. For example, Winsun, a Chinese construction company, has used 3D printing technology to build homes and other structures at a significantly lower cost and with reduced waste compared to traditional construction methods.

Conclusion

3D printing is a rapidly evolving technology with boundless possibilities for innovation and change. From healthcare and fashion to construction and manufacturing, 3D printing is already having a significant impact on a number of industries and is poised to revolutionize the way we live and work.

Despite the challenges and limitations of 3D printing, the potential benefits and advancements make it an exciting and promising technology to watch in the years to come. Whether you are a student, professional, entrepreneur, or hobbyist, there has never been a better time to explore the world of 3D printing and discover the endless possibilities it has to offer.