Supply Chain Engineering: Optimizing the Flow of Goods and Services

Supply chain engineering is a critical field that ensures the seamless movement of goods and services from one point to another. In today's globalized market, businesses face increasing pressure to deliver products faster, cheaper, and more sustainably. Optimizing supply chains is not just about efficiency; it's about staying competitive. This article delves into the intricacies of supply chain engineering, exploring how innovations in technology and process improvements can streamline operations and drive long-term success.

What is Supply Chain Engineering?

Supply chain engineering is the application of scientific, mathematical, and engineering principles to the design and management of supply chains. It focuses on optimizing the flow of goods, services, and information from suppliers to customers. By engineering supply chain systems, businesses can reduce costs, improve delivery times, and enhance customer satisfaction.

In essence, supply chain engineering aims to design supply chains that are resilient, efficient, and capable of adapting to market fluctuations.

Why Supply Chain Optimization Matters

In the fast-paced world of commerce, supply chain efficiency is critical. Companies that fail to optimize their supply chains face higher operational costs, delayed deliveries, and dissatisfied customers. On the other hand, businesses that invest in supply chain engineering enjoy:

-

Cost Savings: By streamlining operations, companies can reduce waste, minimize excess inventory, and lower transportation costs.

-

Faster Delivery: Optimized supply chains enable quicker delivery of products, enhancing customer satisfaction and brand loyalty.

-

Risk Mitigation: A well-engineered supply chain can anticipate and respond to disruptions, whether due to natural disasters, political instability, or supply shortages.

-

Sustainability: Eco-friendly practices are gaining importance, and optimized supply chains reduce carbon footprints through efficient use of resources and smart logistics planning.

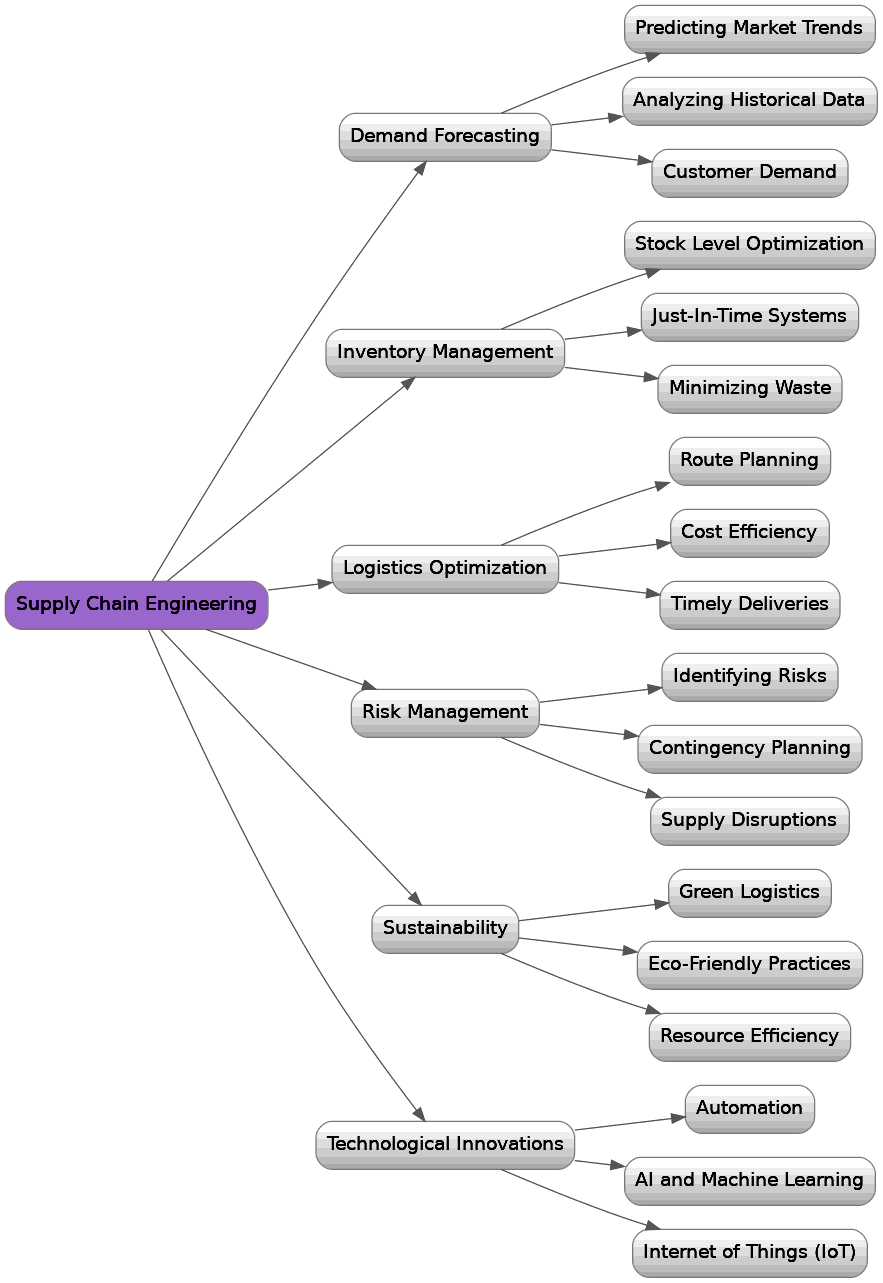

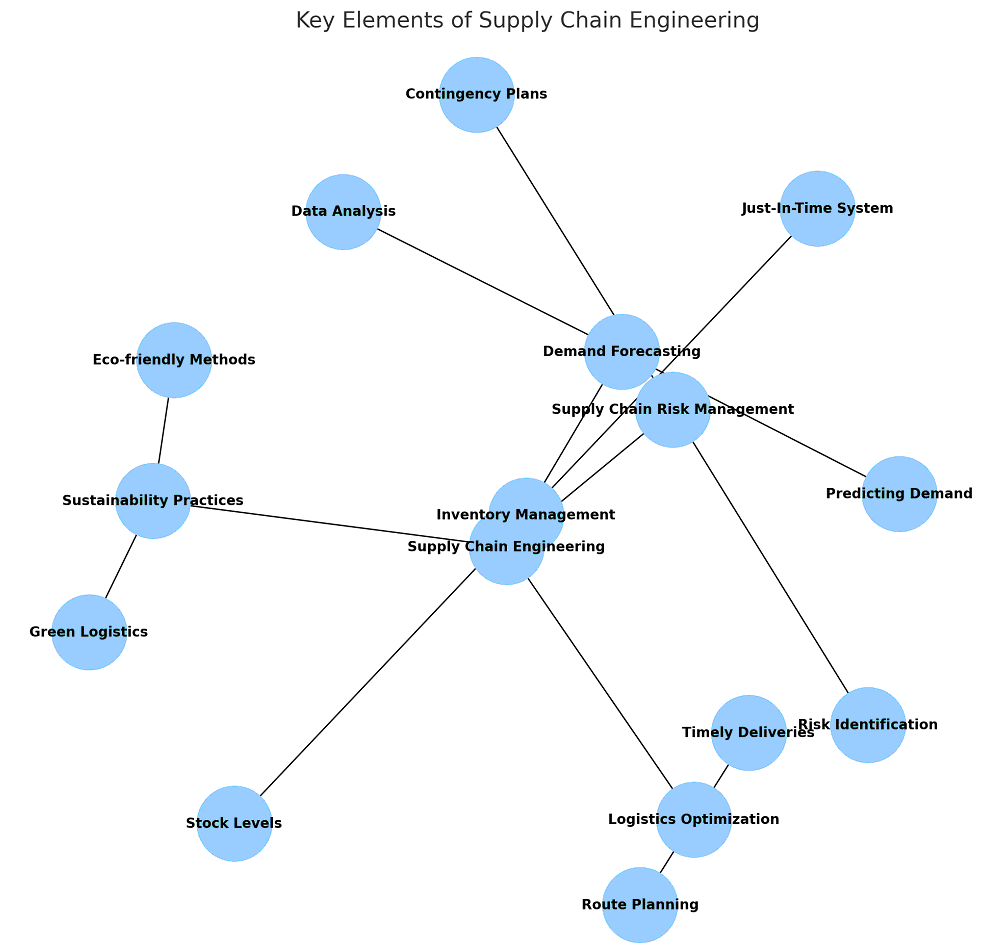

Key Elements of Supply Chain Engineering

1. Demand Forecasting

Demand forecasting is the process of predicting customer demand to ensure that the right amount of product is available at the right time. By analyzing historical data, market trends, and customer behaviors, businesses can accurately forecast demand and plan their inventory levels accordingly.

2. Inventory Management

Proper inventory management is a cornerstone of supply chain efficiency. It involves maintaining the ideal stock levels to meet customer demand without overproducing or underproducing. Tools like Just-In-Time (JIT) and automated inventory systems help businesses minimize holding costs and reduce waste.

3. Logistics and Transportation Optimization

Efficient logistics management involves optimizing routes, choosing the right carriers, and ensuring timely deliveries. With the help of advanced logistics tools and software, companies can determine the most cost-effective and quickest routes for transporting goods. This not only cuts costs but also minimizes delays and enhances overall supply chain performance.

4. Supply Chain Risk Management

Disruptions in the supply chain, such as natural disasters, geopolitical issues, or supply shortages, can severely affect business operations. Supply chain engineering includes risk management strategies that help companies identify potential risks and create contingency plans. These might include diversifying suppliers, stockpiling critical resources, or implementing redundant systems.

5. Sustainability in Supply Chain

Sustainability is no longer optional; it's essential. Optimizing supply chains to be environmentally friendly can improve brand reputation and customer loyalty. Sustainable practices such as reducing packaging waste, optimizing transportation routes to cut emissions, and sourcing raw materials from ethical suppliers are becoming common in modern supply chain engineering.

Innovations in Supply Chain Engineering

1. Automation and Robotics

Automation has transformed supply chain processes. Automated warehouses, where robots pick, pack, and ship items, reduce human error and speed up operations. Additionally, automated tracking systems provide real-time updates on inventory levels, ensuring that businesses can make data-driven decisions quickly.

2. Artificial Intelligence (AI) and Machine Learning

AI and machine learning are revolutionizing supply chain management by improving demand forecasting, optimizing logistics, and enhancing decision-making. AI-driven systems can analyze vast amounts of data to predict trends and suggest operational improvements. For example, AI can suggest better supplier relationships, adjust inventory levels dynamically, or optimize routes for transportation.

3. Blockchain Technology

Blockchain ensures transparency and security in supply chain transactions. By providing a secure and immutable ledger, blockchain allows all stakeholders to track the movement of goods from production to delivery. This not only enhances trust but also helps in verifying the authenticity of products, reducing fraud, and ensuring compliance with industry standards.

4. The Internet of Things (IoT)

IoT devices collect and share real-time data across the supply chain, offering valuable insights into the condition and location of goods. IoT sensors can monitor temperature, humidity, and even vibration levels, ensuring that sensitive products like pharmaceuticals or perishables are transported under optimal conditions. This technology significantly reduces the risk of damage and enhances product safety.

5. Sustainable Packaging and Green Logistics

As businesses prioritize sustainability, supply chain engineers are exploring greener logistics solutions. This includes optimizing packaging to reduce waste, using biodegradable materials, and employing energy-efficient transportation methods. Additionally, green logistics focuses on reducing carbon emissions by optimizing delivery routes and using electric vehicles.

Case Studies: Companies Leading the Way in Supply Chain Optimization

1. Amazon

Amazon's supply chain is known for its speed and efficiency. By investing in automation, robotics, and AI, the company has created a system where customers can order products and receive them within hours. Their sophisticated inventory management systems ensure that the right products are always available, minimizing stockouts and excess inventory.

2. Walmart

Walmart has built one of the most advanced supply chain systems in the world. Through a combination of demand forecasting, inventory management, and real-time tracking, the company ensures that its stores are always well-stocked. Walmart's focus on sustainability, including reducing emissions and waste in its supply chain, has also set a standard for other retailers.

3. Unilever

Unilever has taken significant steps toward optimizing its supply chain while prioritizing sustainability. The company has reduced its carbon footprint by optimizing its logistics network and sourcing materials from ethical suppliers. Unilever's supply chain innovations also include digital tracking systems that enhance transparency and efficiency.

How to Optimize Your Supply Chain

-

Invest in Technology: Automation, AI, and IoT devices can drastically improve the efficiency and visibility of your supply chain. Consider integrating these technologies to gain real-time insights and streamline operations.

-

Focus on Data: Data-driven decision-making is key to optimizing supply chains. Use advanced analytics to predict customer demand, optimize inventory levels, and manage logistics more effectively.

-

Develop Strong Supplier Relationships: A resilient supply chain depends on strong relationships with reliable suppliers. Ensure that your suppliers meet your company’s ethical and sustainability standards and have contingency plans for any disruptions.

-

Implement Sustainability Practices: Sustainability is not just a trend but a necessity. Optimize your supply chain by reducing waste, using energy-efficient transportation, and sourcing sustainable materials.

-

Train and Empower Your Team: Human capital is still essential in supply chain management. Invest in training your team to use the latest technologies and follow best practices in logistics, inventory management, and risk mitigation.

Conclusion

Supply chain engineering plays a crucial role in helping businesses stay competitive in today’s fast-paced market. By optimizing the flow of goods and services, companies can reduce costs, improve efficiency, and provide a better customer experience. Innovations such as AI, IoT, and blockchain are transforming the field, offering businesses new ways to optimize their operations. As the focus on sustainability grows, supply chain engineers must incorporate eco-friendly practices into their designs. Ultimately, supply chain engineering is about creating systems that are efficient, resilient, and adaptable to the ever-changing demands of the market.