Plasma Engineering: Applications in Industry and Research

Plasma engineering is revolutionizing multiple industries and advancing cutting-edge research in ways that were unimaginable just a few decades ago. From high-precision manufacturing processes to groundbreaking applications in environmental sustainability, plasma technology is proving to be a pivotal force. In this article, we will explore how plasma engineering is being utilized in various industrial settings and how it is driving advancements in scientific research.

What is Plasma Engineering?

Plasma, often referred to as the fourth state of matter, is an ionized gas that contains free-moving electrons and ions. It can be generated by applying heat or electricity to a gas, causing the gas particles to ionize. Plasma engineering is the application of this ionized gas in industrial and research settings to manipulate materials, modify surfaces, and perform high-energy reactions.

Plasma technology stands out due to its unique ability to operate at extreme temperatures and energies, which allows it to achieve results that would be impossible with conventional methods. These properties make plasma engineering a versatile tool across a variety of industries, ranging from electronics to healthcare.

Industrial Applications of Plasma Engineering

Plasma in Manufacturing and Surface Engineering

One of the most prominent uses of plasma engineering is in surface modification and treatment, particularly in the manufacturing sector. Plasma is widely used to alter the surface properties of materials without affecting the bulk material. For example, in the automotive industry, plasma is used to improve adhesion, corrosion resistance, and surface cleanliness in materials like metals and plastics.

In the electronics industry, plasma engineering is a critical component in the fabrication of semiconductors. Plasma etching is used to precisely remove layers of material, allowing for the creation of microscopic circuits. As semiconductor devices continue to shrink, plasma’s ability to work on a nanoscale level becomes even more crucial.

In plasma arc cutting, a high-velocity jet of ionized gas is used to cut through metal with extreme precision and speed. This process is widely utilized in heavy industries such as shipbuilding, aerospace, and automotive manufacturing, where precision and efficiency are paramount.

Plasma in Environmental Solutions

Beyond manufacturing, plasma technology is also being utilized to tackle environmental challenges. Plasma-based waste treatment is gaining traction as a method for reducing hazardous waste and converting it into safer byproducts. This is especially valuable in industries such as chemical manufacturing and waste management, where traditional waste treatment methods may be ineffective or harmful to the environment.

Another application is in air and water purification. Plasma can break down harmful pollutants and pathogens in both air and water, offering an eco-friendly solution for environmental decontamination. These plasma-based systems are increasingly being adopted in hospitals, factories, and municipal facilities, where sanitation and environmental sustainability are key concerns.

Plasma Sterilization in Healthcare

In the healthcare industry, plasma engineering plays a significant role in sterilization and disinfection. Cold plasma is particularly effective at eliminating bacteria, viruses, and other pathogens from surfaces and medical devices. Unlike traditional sterilization methods, plasma does not require high temperatures, making it ideal for heat-sensitive instruments.

Plasma also shows promise in advanced medical treatments. Plasma medicine, an emerging field, explores the use of plasma in wound healing, cancer treatment, and tissue regeneration. While still in its early stages, plasma medicine represents a frontier in healthcare innovation, offering new ways to treat and manage a variety of conditions.

Plasma Engineering in Research

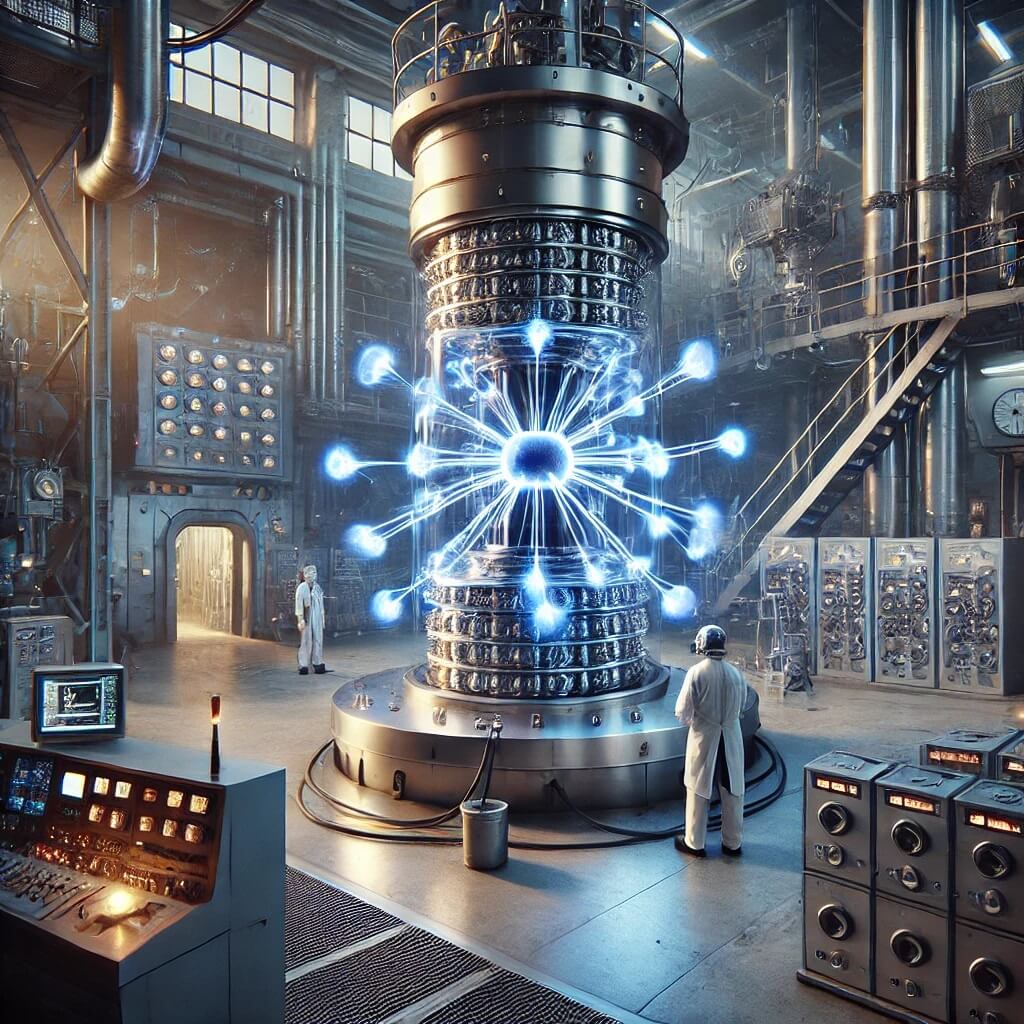

Advancements in Fusion Energy

One of the most ambitious applications of plasma engineering in research is in the field of fusion energy. Fusion energy aims to replicate the process that powers the sun by fusing atomic nuclei to release vast amounts of energy. Plasma confinement is a crucial component of this process, as plasma needs to be contained at extremely high temperatures to facilitate nuclear fusion.

Research facilities such as the ITER project are at the forefront of exploring fusion energy’s potential. While commercial fusion power is still a long way off, the advancements in plasma physics driven by this research are helping scientists better understand how to control and manipulate plasma for energy production.

Plasma in Nanotechnology and Materials Science

Plasma engineering is also making strides in nanotechnology and materials science. Plasma-enhanced chemical vapor deposition (PECVD) is used to deposit thin films of materials onto surfaces, a process vital in creating nanostructures for use in electronics, optics, and coatings. This has far-reaching implications for industries ranging from microelectronics to renewable energy, where precision at the nanoscale level is critical.

Additionally, plasma-based surface engineering allows scientists to manipulate the physical and chemical properties of materials, such as hardness, conductivity, and corrosion resistance. This opens up new possibilities for creating materials with tailored properties for specific applications, pushing the boundaries of materials science.

Plasma in Space Exploration

Plasma engineering is also a critical technology in space exploration, particularly in the development of advanced propulsion systems. Plasma thrusters, which generate thrust by accelerating ionized gas, offer a highly efficient means of propelling spacecraft. These systems are already being tested on various space missions and are expected to play a crucial role in long-duration space travel.

As plasma technology continues to evolve, it holds the potential to enable faster, more efficient space travel, making destinations like Mars and beyond more accessible.

Challenges in Plasma Engineering

While the potential of plasma engineering is vast, there are also several challenges that must be addressed for the technology to reach its full potential.

High Energy Consumption

One of the primary challenges of plasma engineering is its high energy consumption. Generating and maintaining plasma requires significant amounts of electricity, making it costly for large-scale industrial applications. As energy efficiency becomes increasingly important in manufacturing, finding ways to reduce the energy demands of plasma processes is a key area of focus.

Material Compatibility

Another challenge is material compatibility. Not all materials are suitable for plasma-based processes, as the high temperatures and ionizing nature of plasma can degrade or damage certain substances. This limits the broader adoption of plasma in industries where material flexibility is crucial.

Complex Equipment and Technical Expertise

The equipment required to generate, control, and manipulate plasma is highly specialized and often expensive. Furthermore, plasma engineering demands a high level of technical expertise, which can be a barrier to entry for smaller companies or industries without access to specialized training and resources.

Future Trends in Plasma Engineering

Despite these challenges, plasma engineering is poised for continued growth and innovation. As industries place more emphasis on sustainability and efficiency, plasma-based technologies are likely to play a larger role in addressing these needs.

Advancements in energy-efficient plasma systems, such as those powered by renewable energy sources, could help mitigate the high energy demands of plasma processes. Additionally, ongoing research in plasma materials science is expected to expand the range of materials that can be used in plasma-based applications.

In healthcare, plasma medicine is likely to continue advancing, offering new treatments and therapies for conditions that are difficult to treat with traditional methods. Similarly, in the space sector, plasma thrusters will play an increasingly important role in deep space exploration, helping humanity reach new frontiers.

Conclusion

Plasma engineering is a rapidly evolving field with diverse applications in industry and research. From precision manufacturing to environmental solutions, and from nanotechnology to space exploration, plasma technology is proving to be a game-changer. While there are challenges in terms of energy consumption and equipment complexity, the potential benefits of plasma engineering far outweigh these obstacles.

As the technology continues to advance, it is clear that plasma will play an increasingly important role in shaping the future of industries and research worldwide. Whether you're an engineer looking to improve industrial processes or a researcher pushing the boundaries of scientific discovery, plasma engineering offers exciting opportunities for innovation.

Call to Action

Ready to explore more about how plasma engineering can transform your industry or research? Stay updated with the latest trends and advancements in plasma technology by subscribing to our newsletter or sharing this article with your colleagues.