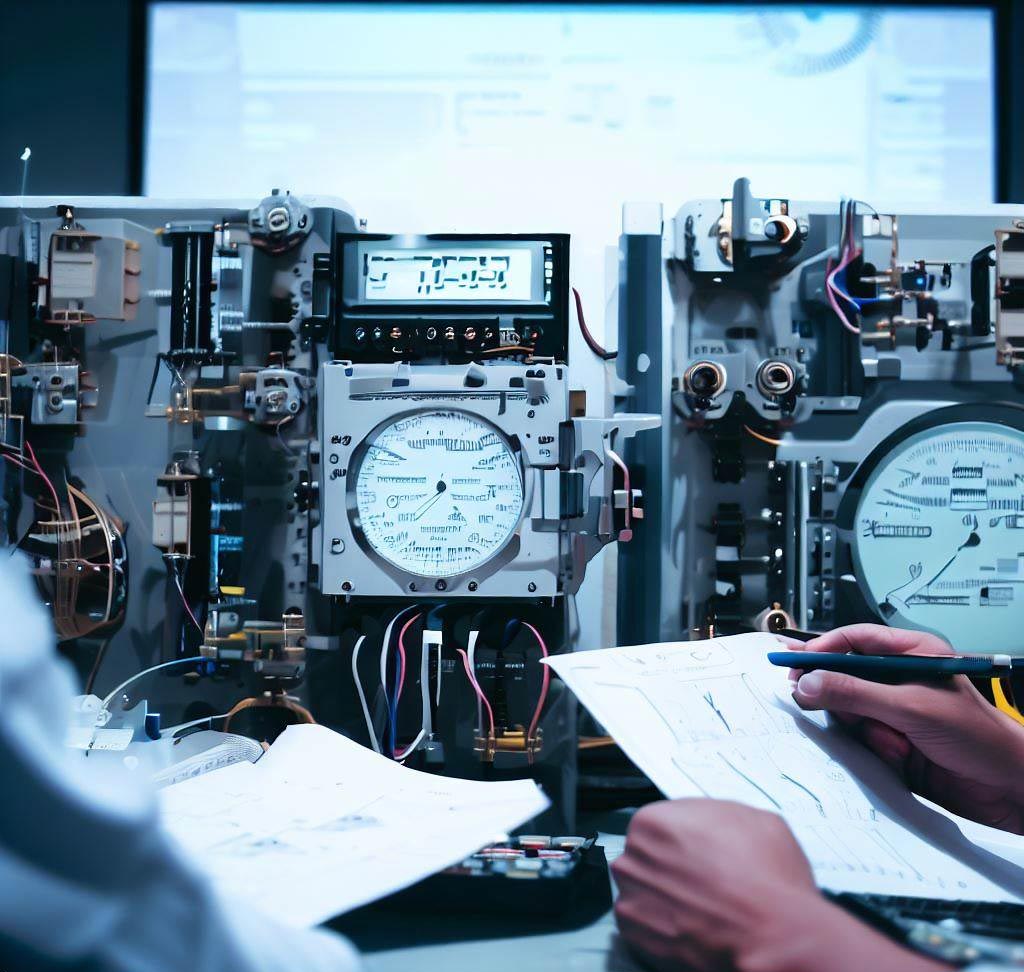

Instrumentation Engineering Course: An Overview

Instrumentation Engineering is a specialized field of engineering that focuses on the design, development, installation, and maintenance of instruments and control systems used in various industries. It combines principles from electrical, electronic, and measurement engineering to ensure accurate and reliable control and monitoring of processes.

Instrumentation Engineering Course Highlights

- In-depth study of instrumentation principles, control systems, sensors, transducers, signal processing, and automation.

- Practical training on designing, implementing, and troubleshooting instrumentation systems.

- Exposure to various industry-standard software and tools used in instrumentation engineering.

- Emphasis on hands-on experience through lab experiments, industrial visits, and internships.

- Integration of theoretical concepts with real-world applications to develop problem-solving skills.

Types of Instrumentation Engineering Courses

- Bachelor's Degree: A four-year undergraduate program that provides a comprehensive foundation in instrumentation engineering.

- Master's Degree: A two-year postgraduate program that offers advanced knowledge and specialization in instrumentation engineering.

- Diploma Courses: Short-term courses that focus on specific aspects of instrumentation engineering, suitable for individuals seeking quick skill enhancement.

- Certification Courses: Specialized courses that validate expertise in specific areas of instrumentation engineering, such as industrial automation, process control, or calibration.

List of Popular Instrumentation Engineering Specializations

- Process Control Instrumentation: Focuses on designing and implementing control systems for industrial processes, ensuring optimal operation and efficiency.

- Biomedical Instrumentation: Concentrates on developing instruments and devices for medical diagnostics, monitoring, and treatment.

- Environmental Instrumentation: Involves designing and deploying instruments to measure and analyze environmental parameters for research and monitoring purposes.

- Industrial Automation: Covers the application of automated control systems in industrial processes to improve productivity and safety.

- Instrumentation in Oil and Gas: Deals with the design and installation of instrumentation systems used in the oil and gas industry for exploration, extraction, and refining processes.

Course Outlines

- Basics of Instrumentation Engineering

- Electrical and Electronic Circuits

- Sensors and Transducers

- Signal Conditioning and Processing

- Control Systems

- Industrial Instrumentation

- Process Control

- Programmable Logic Controllers (PLCs)

- Distributed Control Systems (DCS)

- Industrial Automation

- Instrumentation Design and Calibration

- Safety Instrumented Systems

- Data Acquisition and Analysis

- Project Work and Internships

Instrumentation Engineering Minimum Qualification Required

To pursue a course in Instrumentation Engineering, the minimum educational qualification required is a high school diploma or equivalent. However, for higher-level programs such as a Bachelor's or Master's degree, candidates need to fulfill the specific eligibility criteria set by the respective educational institutions.

Required Skillset for Instrumentation Engineering

- Strong foundation in mathematics, physics, and engineering principles.

- Proficiency in electrical circuit analysis and electronic devices.

- Knowledge of control systems and automation techniques.

- Familiarity with programming languages and software used in instrumentation engineering.

- Analytical and problem-solving skills to diagnose and resolve issues with instrumentation systems.

- Attention to detail and ability to work with precision in designing and calibrating instruments.

- Effective communication and teamwork skills for collaborating with engineers and technicians from different disciplines.

Learning Outcomes

Upon completing an Instrumentation Engineering course, students can expect to:

- Demonstrate a solid understanding of instrumentation principles, control systems, and measurement techniques.

- Design and implement instrumentation systems for various industrial applications.

- Apply knowledge of sensors, transducers, and signal processing techniques to acquire and process accurate data.

- Analyze and interpret data to make informed decisions regarding process control and optimization.

- Troubleshoot and maintain instrumentation systems to ensure their reliable and efficient operation.

- Stay updated with emerging trends and technologies in the field of instrumentation engineering.

Why Choose Instrumentation Engineering?

Instrumentation Engineering offers several compelling reasons for students to choose it as a career path:

- Lucrative Career Opportunities: Instrumentation engineers are in high demand across industries such as oil and gas, manufacturing, healthcare, and environmental monitoring.

- Technological Advancements: With rapid advancements in automation, Industry 4.0, and Internet of Things (IoT), instrumentation engineering professionals play a crucial role in designing and implementing cutting-edge systems.

- Challenging and Rewarding Work: Instrumentation engineers face complex problems and are responsible for ensuring the smooth operation of critical processes, making their work intellectually stimulating and impactful.

- Versatile Skill Set: The skills acquired in instrumentation engineering are transferable to various domains, providing flexibility and diverse career options.

- Continuous Learning and Growth: The field of instrumentation engineering is dynamic, offering ample opportunities for learning and professional development.

Scope

The scope for instrumentation engineers is vast and expanding. They play a pivotal role in industries that rely on accurate monitoring and control of processes, including manufacturing, energy, pharmaceuticals, automotive, aerospace, and more. With the increasing emphasis on automation and data-driven decision-making, the demand for skilled instrumentation engineers is expected to grow significantly.

Job Outlook

The job outlook for instrumentation engineers is promising, with ample career opportunities in both national and international markets. Graduates can pursue various roles such as Instrumentation Engineer, Control System Engineer, Automation Engineer, Process Engineer, Calibration Engineer, and Research and Development Engineer. Additionally, they can explore opportunities in project management, consulting, and entrepreneurship.

Instrumentation Engineering Career Options and Job Prospects

Instrumentation engineering graduates can find employment in various sectors, including:

- Manufacturing Industries: Companies involved in manufacturing automobiles, consumer goods, chemicals, and textiles require instrumentation engineers to ensure efficient and safe production processes.

- Oil and Gas Industry: Instrumentation engineers play a crucial role in designing and maintaining instrumentation systems used in oil refineries, drilling rigs, and pipeline networks.

- Power Generation and Utilities: Power plants and utilities rely on instrumentation engineers for the operation and control of critical systems, ensuring reliable and efficient power generation.

- Healthcare and Biomedical Companies: Instrumentation engineers contribute to the development and maintenance of medical devices and equipment used in hospitals and research facilities.

- Environmental Monitoring: Government agencies and private organizations involved in environmental monitoring and research hire instrumentation engineers to design and deploy monitoring systems.

Courses After Instrumentation Engineering

After completing a course in Instrumentation Engineering, individuals can pursue higher studies or specialized courses to enhance their knowledge and career prospects. Some popular options include:

- Master's degree in Instrumentation Engineering or related fields such as Control Systems Engineering, Industrial Automation, or Biomedical Engineering.

- MBA or Management courses to develop business and leadership skills for managerial positions.

- Certification programs in specific technologies or software used in instrumentation engineering, such as SCADA, PLC programming, or LabVIEW.

Challenges

Instrumentation engineering comes with its own set of challenges:

- Complex Problem Solving: Instrumentation engineers often encounter complex issues that require in-depth analysis and troubleshooting skills.

- Rapid Technological Advancements: Keeping up with the latest advancements in automation, software, and communication technologies can be challenging.

- Adapting to Industry-specific Requirements: Different industries may have specific requirements and standards for instrumentation systems, necessitating continuous learning and adaptation.

- Safety and Reliability: Instrumentation engineers must ensure that the systems they design and maintain meet stringent safety and reliability standards, considering the potential risks involved in critical processes.

Limitations

Despite its advantages, instrumentation engineering has a few limitations:

- Limited Availability of Specialized Courses: Some specialized areas within instrumentation engineering may have limited course options or resources, requiring individuals to seek additional training or self-study.

- Technical Complexity: The field of instrumentation engineering can be technically complex, demanding a strong foundation in mathematics, physics, and engineering principles.

- Industry-specific Skills: The application of instrumentation engineering principles can vary across industries, necessitating the acquisition of industry-specific skills and knowledge.

- Continuous Learning: To stay relevant in this field, professionals need to engage in continuous learning and keep up with emerging trends and technologies.

Emerging Trends

- Internet of Things (IoT): The integration of sensors, actuators, and communication technologies is enabling advanced monitoring and control systems, creating opportunities for instrumentation engineers.

- Data Analytics and Machine Learning: Leveraging data analytics and machine learning techniques can enhance the predictive capabilities of instrumentation systems, enabling proactive maintenance and optimization.

- Cybersecurity: As instrumentation systems become more interconnected, the need for robust cybersecurity measures to protect against threats and vulnerabilities is gaining importance.

- Sustainable Instrumentation: With a growing emphasis on sustainability, instrumentation engineers are exploring eco-friendly and energy-efficient solutions for instrumentation systems.

FAQs about Instrumentation Engineering

|

1. What is the difference between Instrumentation Engineering and Electronics Engineering? Instrumentation Engineering focuses on the design and implementation of instruments and control systems, while Electronics Engineering deals with the design and development of electronic circuits and devices in general. 2. What are the key skills required to excel in Instrumentation Engineering? Key skills for Instrumentation Engineering include knowledge of electrical circuits, control systems, programming, analytical thinking, problem-solving, attention to detail, and effective communication. 3. How does Instrumentation Engineering contribute to industrial automation? Instrumentation Engineering plays a crucial role in industrial automation by designing and implementing control systems, sensors, and actuators that automate and optimize industrial processes for increased efficiency and productivity. 4. What are the job prospects for Instrumentation Engineering graduates? Instrumentation Engineering graduates have promising job prospects in industries such as manufacturing, oil and gas, power generation, healthcare, and environmental monitoring, with opportunities for roles such as Instrumentation Engineer, Control System Engineer, and Automation Engineer. 5. Can Instrumentation Engineers work in research and development? Yes, Instrumentation Engineers can work in research and development roles, where they contribute to the development of new instrumentation technologies, devices, and systems for various applications. 6. Are there any international career opportunities for Instrumentation Engineers? Yes, Instrumentation Engineers can explore international career opportunities, especially in industries such as oil and gas, manufacturing, and automation, where their expertise is in high demand worldwide. 7. What is the role of Instrumentation Engineering in the pharmaceutical industry? Instrumentation Engineering plays a vital role in the pharmaceutical industry by designing and maintaining instrumentation systems used in research laboratories, manufacturing processes, quality control, and compliance with regulatory standards. 8. How can I specialize in a specific area within Instrumentation Engineering? To specialize in a specific area within Instrumentation Engineering, you can pursue advanced courses, certifications, or higher studies focusing on specialized fields such as process control, biomedical instrumentation, industrial automation, or environmental instrumentation. 9. What are the software tools used in Instrumentation Engineering? Instrumentation Engineering utilizes various software tools such as SCADA (Supervisory Control and Data Acquisition), PLC (Programmable Logic Controller) programming software, HMI (Human-Machine Interface) software, and simulation tools like MATLAB and LabVIEW. 10. How can I stay updated with the latest advancements in Instrumentation Engineering? To stay updated with the latest advancements, you can join professional organizations, attend conferences and seminars, participate in online forums and communities, read industry publications, follow influential blogs and social media accounts, and engage in continuous learning and professional development activities. |