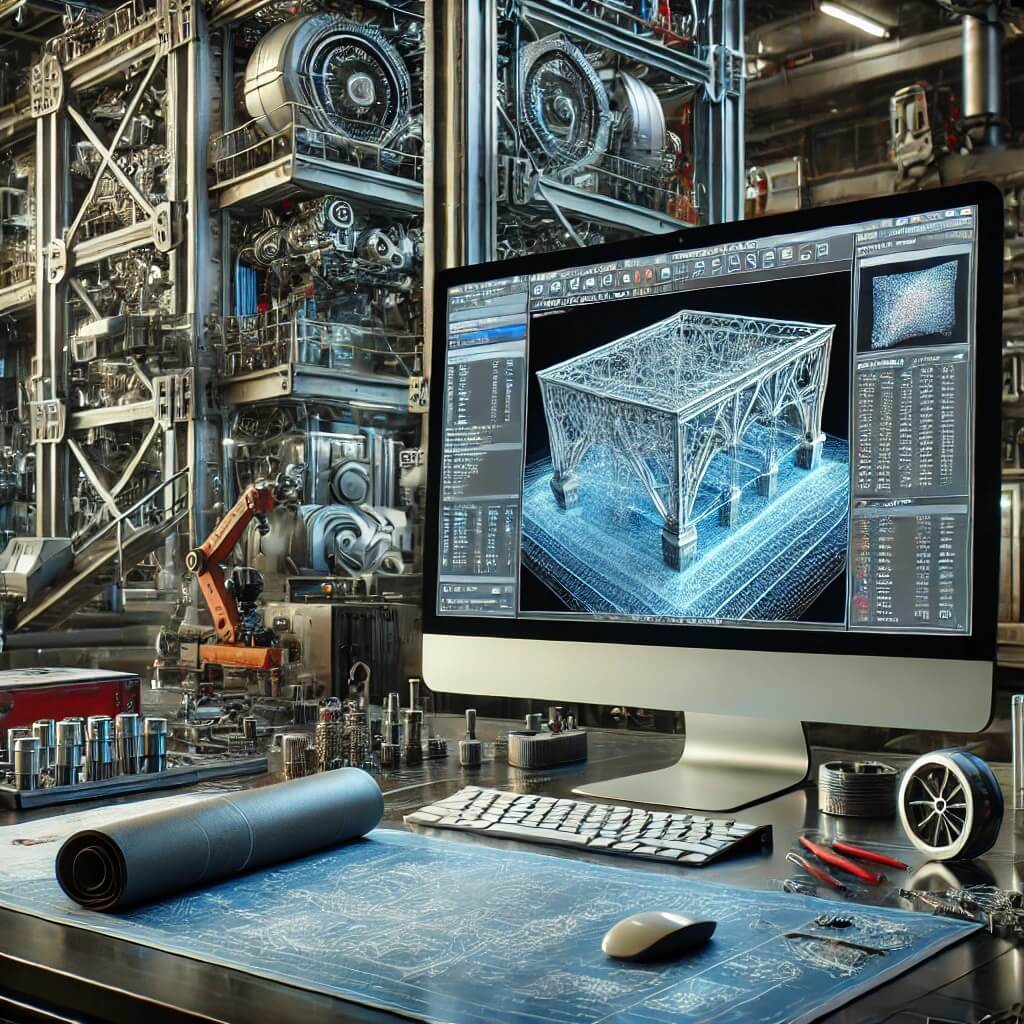

Computational Modeling and Simulation in Engineering: Optimize Your Design with Cutting-Edge Techniques

Introduction

In today's rapidly advancing technological landscape, engineering solutions require a high degree of precision, speed, and cost-effectiveness. Computational modeling and simulation have become essential tools for engineers, enabling them to predict real-world behavior, optimize complex systems, and reduce the need for physical prototypes. But what exactly is computational modeling in engineering, and how can it benefit your projects? This article will explore the fundamentals of computational modeling and simulation, diving into the techniques, applications, and advantages that these powerful tools bring to modern engineering.

What is Computational Modeling in Engineering?

At its core, computational modeling in engineering involves creating digital representations of physical systems or processes using mathematical equations and algorithms. These models are then tested through simulation, where various scenarios and conditions are applied to observe how the system behaves. Whether it's testing the durability of a bridge design or the fluid dynamics in a car engine, computational models allow engineers to experiment with different variables without the risks or costs associated with physical testing.

Applications of Computational Modeling in Engineering

Computational modeling can be applied across numerous fields of engineering, including:

-

Mechanical Engineering: Simulating the behavior of materials, machinery, and mechanical systems under different conditions. For example, finite element analysis (FEA) is used to predict how a structure will react to forces, vibrations, and other physical effects.

-

Civil Engineering: Computational modeling helps design safe and efficient infrastructure. Structural simulations predict the stability of bridges, dams, and buildings under different loads and environmental conditions.

-

Aerospace Engineering:

In aerospace, simulations help engineers design aircraft and spacecraft by modeling aerodynamics, propulsion, and structural integrity. Computational fluid dynamics (CFD) is commonly used to study airflow around wings and fuselages. -

Electrical Engineering: Modeling the behavior of electrical systems, such as circuits and electromagnetic fields, helps engineers design and optimize electrical devices with improved efficiency and safety.

-

Chemical and Environmental Engineering:

Engineers can simulate chemical reactions and environmental processes, such as pollutant dispersion or chemical plant safety, ensuring compliance with environmental regulations and reducing risks.

Advantages of Computational Modeling and Simulation

Why are computational models so critical in engineering today? The benefits are extensive, making it a preferred approach for engineers worldwide:

-

Cost-Effectiveness: By simulating scenarios digitally, engineers can avoid costly physical prototypes and reduce the need for extensive material use. This can lead to significant cost savings, especially in industries like aerospace and automotive, where prototypes can be prohibitively expensive.

-

Time Efficiency: Instead of waiting for physical tests to provide results, simulations offer immediate feedback. This accelerates the design process, allowing engineers to make quicker adjustments and bring products to market faster.

-

Improved Accuracy: Computational models provide highly accurate predictions about how a system will behave under specific conditions. Advanced tools like FEA and CFD allow engineers to simulate everything from material stress to fluid flow with remarkable precision.

-

Optimization of Complex Systems: Engineers can test multiple variables and conditions at once, helping them identify the optimal configuration for a system. This is particularly useful for large projects where many factors, such as material properties, load conditions, and environmental impacts, must be considered.

-

Risk Mitigation: With simulations, engineers can test how a system performs under extreme or rare conditions without endangering lives or equipment. This enhances safety by predicting potential failure points and mitigating risks before they arise in real-world applications.

Challenges in Computational Modeling

While the advantages of computational modeling are clear, there are some challenges engineers face when implementing these techniques:

-

Computational Resource Requirements: Large, complex simulations can require substantial computational power and time. For example, CFD simulations involving millions of data points can take hours or even days to compute without high-performance computing resources.

-

Model Complexity and Expertise: Developing accurate computational models requires a deep understanding of both engineering principles and mathematical algorithms. Engineers must ensure that their models reflect real-world physics as accurately as possible, which can be a complex and time-consuming process.

-

Data Quality: The accuracy of simulation results depends heavily on the quality of the input data. Poor-quality data or incorrect assumptions can lead to misleading or inaccurate results, potentially jeopardizing the design.

Key Techniques in Computational Engineering

-

Finite Element Analysis (FEA): FEA is a numerical method used to predict how a structure or material will react to external forces, heat, and other physical effects. This method divides a large system into smaller, simpler parts called finite elements. These elements are analyzed individually, and the results are combined to give a comprehensive understanding of the entire system's behavior. FEA is commonly used in mechanical, civil, and aerospace engineering.

-

Computational Fluid Dynamics (CFD): CFD focuses on solving and analyzing fluid flow problems using numerical methods and algorithms. It simulates how liquids and gases interact with surfaces and other materials, making it invaluable in fields such as aerodynamics, HVAC design, and environmental engineering.

-

Multibody Dynamics (MBD): MBD simulations predict the motion of interconnected rigid or flexible bodies under the influence of forces. This method is particularly useful in mechanical engineering for designing complex systems like engines, robotics, or vehicles where multiple components interact.

Tools and Software for Computational Modeling

Several software tools are widely used in computational modeling across various industries. Some of the most popular include:

- ANSYS: Known for its powerful FEA and CFD capabilities, ANSYS is a comprehensive simulation software used in multiple engineering fields.

- SolidWorks Simulation: Popular among mechanical engineers, SolidWorks provides integrated simulation tools for testing material strength, fluid flow, and thermal analysis.

- MATLAB: Frequently used in academia and research, MATLAB offers powerful computational modeling capabilities, particularly in control systems and electrical engineering.

- Simulink: Often used in conjunction with MATLAB, Simulink provides a graphical environment for modeling, simulating, and analyzing dynamic systems.

- OpenFOAM: An open-source CFD software widely used in research and academia for solving complex fluid flow problems.

Future of Computational Modeling and Simulation in Engineering

As technology continues to evolve, computational modeling and simulation will become even more integral to engineering practices. Advances in machine learning and artificial intelligence (AI) are already being integrated into simulations, allowing for predictive analytics and automated optimization. These technologies can significantly enhance the speed and accuracy of simulations by identifying patterns and improving decision-making processes.

Additionally, the rise of digital twins, which are virtual replicas of physical systems, is transforming the way engineers design and monitor systems in real-time. Digital twins use live data to continuously update their models, offering engineers a dynamic simulation tool that can predict future system behavior and optimize performance throughout the product lifecycle.

Conclusion

Computational modeling and simulation are revolutionizing engineering design, offering unparalleled accuracy, efficiency, and safety. From finite element analysis (FEA) to computational fluid dynamics (CFD), these tools empower engineers to test, optimize, and innovate without the need for costly physical prototypes. As the field continues to advance, the future promises even greater integration with AI and digital twin technologies, pushing the boundaries of what’s possible in engineering.

If you're an engineer or project manager looking to streamline your design process, now is the time to adopt computational modeling techniques. Start integrating these powerful tools into your workflow to optimize performance, reduce costs, and enhance safety in your engineering projects.

Computer Engineering Topics